Diesel engines sit at the heart of every serious fleet operation, but meeting modern performance, emissions, and uptime expectations means more than just routine maintenance.

The challenge today is balancing power with efficiency, longevity, and compliance. That’s where aftermarket diesel power components step in. Designed to enhance what factory configurations often limit, they turn dependable engines into precision-tuned assets capable of meeting real-world demand without compromise.

Upgrades like improved air systems, high-efficiency injectors, and advanced turbo kits aren’t about pushing luck; they’re about pushing productivity.

This guide breaks down how to evaluate, install, and maintain the right performance components for your operation and how to calculate if the gains are truly worth the investment.

Setting the Stage: Performance Requirements in Diesel Operations

Heavy hauls and tighter emissions constraints are squeezing the margin for error in diesel operations. Fuel is expensive. Downtime is poison. Stock configurations might satisfy regulatory demands, but when you need maximum efficiency and uptime, they often run out of steam. Aftermarket upgrades are not vanity projects—they are targeted answers to operational strain, built to pull every useful ounce of performance from a workhorse you already own.

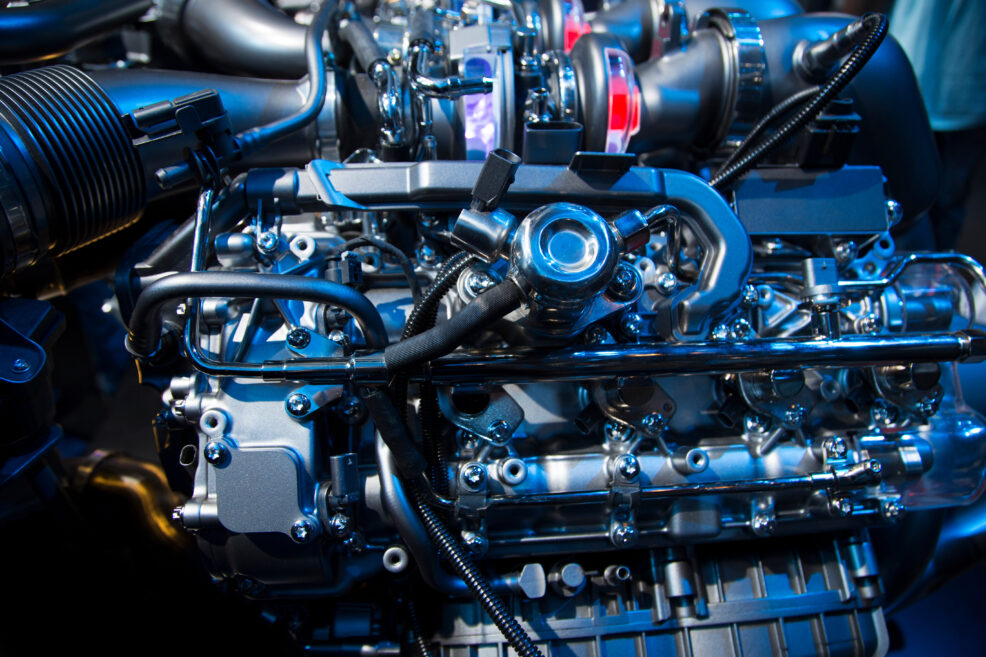

Evaluating Core Diesel Engine Enhancements

Every serious upgrade starts with four pillars: air intake, turbocharging, exhaust, and fuel injection. Each affects how efficiently the engine breathes, burns, and clears exhaust gases.

| Upgrade Type | Main Function | Performance Benefit |

| High-flow Air Intake | Enhances oxygen density | Cleaner, denser combustion |

| Turbocharger Kits | Boosts air compression | Stronger throttle and pulling power |

| Performance Exhaust | Reduces backpressure | Lower heat load, better fuel use |

| Precision injectors | Eliminate transient fuel waste | Smoother power delivery |

OEM parts prioritize compliance and stability; high-performance alternatives leverage advanced metallurgy, optimized geometry, and flow-tested designs to push limits without tearing down reliability.

Tailoring Upgrades to Specific Operating Conditions

There is no universal recipe for diesel optimization. What works on a long-haul truck in Arizona may cripple a snow plow in Alberta. The operating environment dictates the right combination of upgrades.

For example:

- Cold climates: Cold-air intakes keep oxygen-rich air flowing in freezing conditions where standard systems choke.

- Mountain routes: High-boost turbo configurations thrive in thin mountain air where stock units lose torque.

- Urban stop-and-go driving: Long idling cycles demand hardier fuel injectors that can handle extended low-load operation without fouling.

Did you know? Even ambient humidity affects combustion density and turbo efficiency. Fleets operating along coastal regions often see measurable improvements from intercooler upgrades that reduce intake temperature variance.

The goal is not chasing dyno sheet highs. It’s tuning for the grind—balancing peak output with repeatable, day-in-day-out dependability.

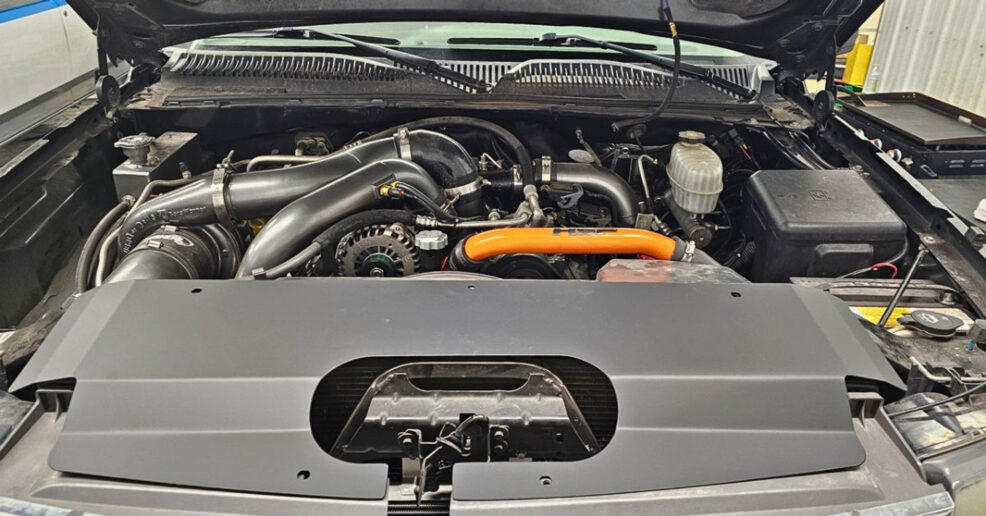

Assessing Component Compatibility and Engine Configurations

Ignoring compatibility checks is a shortcut to mechanical failure. Mixing mismatched components can cause ECU confusion, driveline stress, or transmission failure.

Before installation, always cross-reference:

- Part numbers and engine family identifiers

- Transmission torque ratings (they can cap usable torque no matter how much the engine produces)

- ECU software versions and tuning compatibility

Transmission limits are often ignored,yet even the most powerful turbo means nothing if your gearbox can’t transfer that torque efficiently.

Careful review of manufacturer build sheets and verified fitment data turns keep a “simple upgrade” from becoming a shop-bound headache.

Sourcing Quality Diesel Upgrades and Parts

Vendor choice is a performance decision in itself. Certifications matter. So does data from proper in-house testing, backed with dyno curves and field logs. Top suppliers of diesel performance parts often provide downloadable performance curves and real-world test data.

Trust is earned through proof, not promises. Warranty terms and on-call support can mean the difference between a quick fix and an expensive setback.

Companies that back their components with performance curves and emissions compliance certificates are worth the premium.

Quick Tip: When comparing two vendors, prioritize the one offering live technical support. A 10-minute call before ordering can prevent weeks of downtime from mismatched parts.

Ensuring Smooth Integration: Installation Best Practices

Preparation is where the money is made. Every torque measurement, gasket match, and sealant bead affects whether power gains stick or bleed away. Calibration after installation keeps the upgrade from running blind. Post-install dyno runs confirm gains. Emissions checks catch legal trouble before it leaves the shop. Skipping fit checks or setting boost conservatively avoids the classic pitfalls of premature wear and cascading failure.

Quantifying Gains: Calculating ROI on Aftermarket Diesel Enhancements

Performance talk is cheap without numbers. Fuel burn reduction, improved uptime, fewer unscheduled services, higher resale value—these are the ROI levers that matter.

The ROI equation is simple: (Annual Savings ÷ Upgrade Cost) × 100 = ROI %

| Upgrade Example | Cost | Estimated Payback Period |

| High-efficiency Injectors | $4,000 per truck | 8–9 months |

| Low-restriction Exhaust | $2,000 per truck | 10–12 months |

| Turbocharger Kit | $5,000 per truck | 1 year (fuel + uptime savings) |

Track key metrics: fuel burn rate, maintenance intervals, and uptime hours. Data tells you whether the investment delivers or drains. Without a defined baseline, any “performance improvement” is just an anecdote.

Tracking Performance Metrics Post-Upgrade

Installing performance parts is only half the battle; the real advantage lies in tracking what happens afterward. Data-driven fleets don’t rely on driver impressions; they rely on metrics that prove gains in fuel economy, uptime, and load efficiency.

Key performance indicators (KPIs) to monitor:

- Fuel burn per 100 miles

- Average idle hours vs. productive hours

- Engine load percentage and coolant temperature trends

- Maintenance intervals before vs. after upgrades

Pro Insight: Some fleet managers integrate telematics dashboards that visualize injector pulse width, turbo boost, and torque curves in real time.

With continuous monitoring, you can spot anomalies early, fine-tune calibration settings, and ensure that every upgrade performs exactly as promised over the long haul.

Sustaining Peak Performance with Proactive Maintenance

Upgraded components demand smart maintenance. Fluid analysis grows in importance when pushing higher cylinder pressures. Scheduled inspections on high-stress parts keep small wear from becoming full rebuilds. ECU firmware reviews make sure your engine’s brain stays in sync with its enhanced hardware. Telematics offers early warning before minor inefficiencies morph into breakdowns.

According to fleet data from telematics providers, early detection of injector inefficiency can reduce total repair costs by up to 40% per vehicle annually.

Intelligent upgrades paired with disciplined care can keep a fleet running faster, cleaner, and more profitably over the long haul.